Question:

The shafts on my countermarche loom (Spring or Delta) drop down unevenly

Answer:

This is a common occurrence with parallel countermarch looms such as the Spring and Delta. They don't have a "rest position" for shafts. If you step on a treadle and then release it, not all shafts will drop to the same position. Thanks to this system, pressing the shaft treadles during weaving requires little force. Fortunately this is not a problem during weaving because the warp prevents deep sinking of the shafts and the position of the shafts is neutralized when the next treadle is depressed. The phenomenon also decreases as more treadles and shafts are tied up. (Thus more pronounced for a 4 shaft pattern on a 12 shaft loom).

Below is an explanation of why this is the case and how to deal with it.

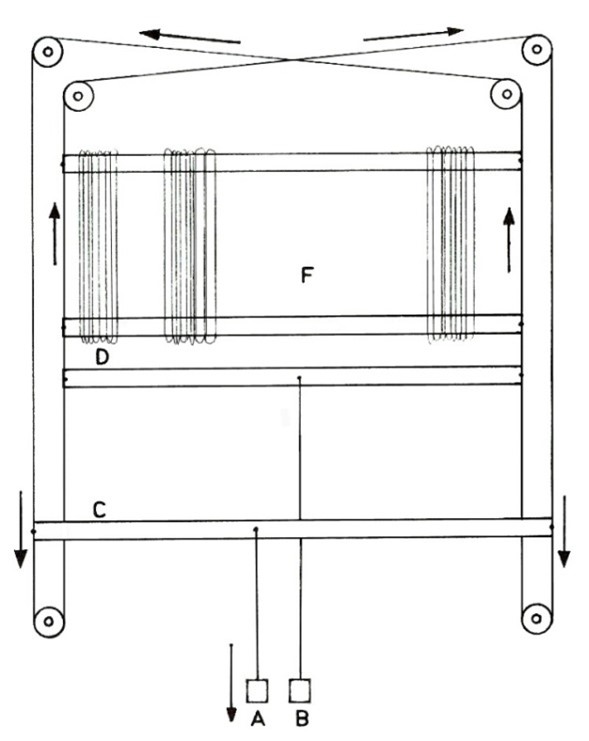

In Louët's parallel countermarch system, a cord runs over six rollers or pulleys. The ends of the cord are connected to each other so that the cord forms a closed circuit. The shaft slats and the lams are connected to these cords. When treadle A is pressed, lam C moves the cord downwards on the outside. The cord on the inside then moves in the opposite direction and pulls shaft F up (see arrows). When treadle B is pressed, lam D pulls the inside of the cord and thus the shaft downwards.

Shaft and lam positions are optimally adjusted in the factory. You can bring the shafts into the neutral position by inserting the blocking pin through the hole provided below the raddle and then through the marked holes in the Texsolv cord. If there is no warp, pull the texsolv cord (left or right) until you find the black mark. After insertion of the blocking pin, the shafts are blocked and prevent movement and the shafts should all be level.

This blocking of the shafts is done during the threading of the warp and during the treadle tie-ups. It is normal that you have to pull the Texsolv cords to put the blocking pin back into the marked holes (see also TIP-1 below). If you remove the blocking pin, the shafts will lower due to gravity. If a warp is threaded, the shafts will not sink as far. During weaving you will notice that the shafts are at the same height due to the treadle movement. You will notice that if you tie-up all treadles and have a wider warp on, the phenomenon of sagging shafts is barely noticeable.

When you attach the treadles with the supplied long and short tie-up cords, you must always use the first hole next to the hole where the cord was cut. With blocked shafts, the tension on all treadles tie-up cords will be approximately the same. During weaving, the blocking pin is out and the image may look a bit irregular due to the lowering of the shafts.

You can check the correct adjustment when the loom is warped and the warp has passed the breast beam while weaving. If you depress two treadles tied up for tabby, at the same time, all shafts will be at the same height and the warp thread should run approximately through the middle of the heddle eye.

TIP-1: If you tie on two treadles that complement each other (for example a tabby tie-up) and depress them at the same time, all shafts are set at the same height and you can easily apply the blocking pin.

TIP-2: If you don't use certain shafts for your draft, you can secure them with the blocking pin during weaving. No pedals can be connected to these shafts.

Comments

0 comments

Please sign in to leave a comment.